This tour shows a range of equipment and facilities available in one of our modern, dedicated laboratories.

The interactive version allows you to walk through the lab and get a 360° view of the facilities.

The EMF lab contains a range of specialist material forming machinery, including:

Students use the hexagonal benches for their group projects.

There are several large vertical storage carousels in the lab. These are used to store all the lab tools and devices.

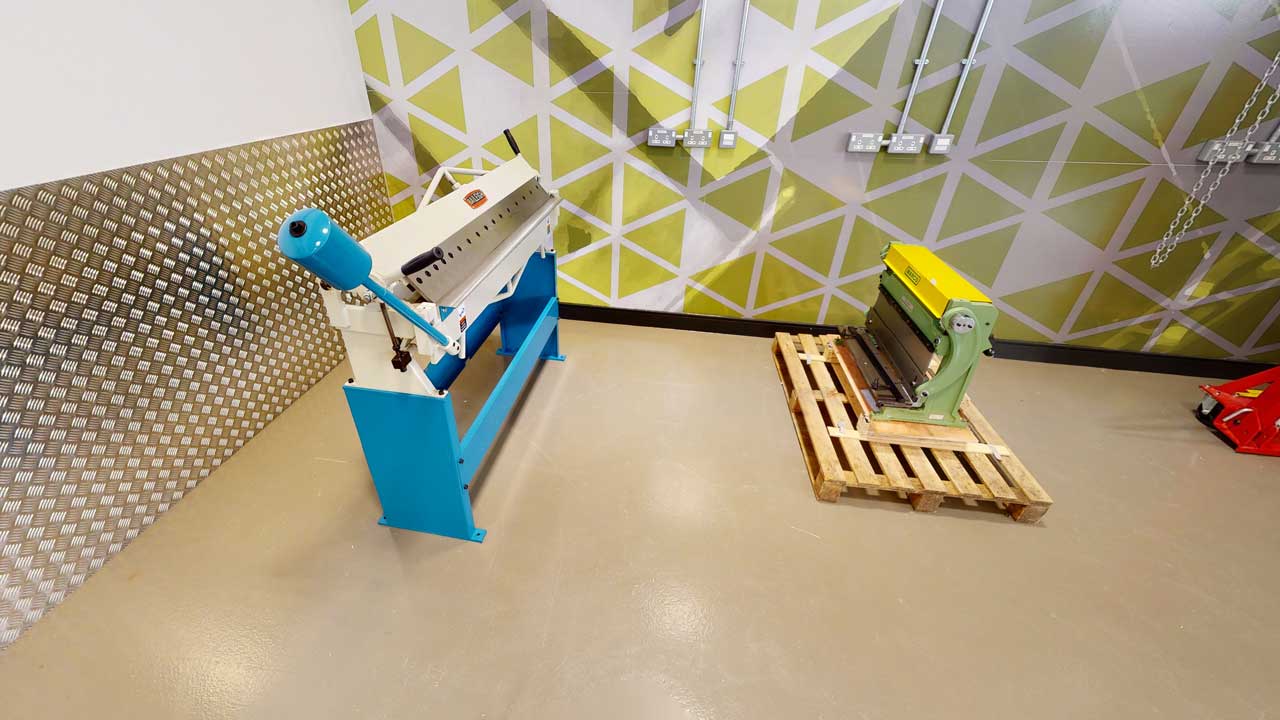

The box and pan folder machines apply pressure to bend metal sheets to create structural profiles.

The laser cutter can make precise cuts to prepare thin metal sheets and polymers.

The thermoforming centre is used for plastic forming, casting and joining.

There are traditional table vices on many workbenches, used for manual mechanical operations, such as drilling and grinding.

Students use the CAD lab for structural design and computer-assisted manufacturing (CAM) simulations.

The bandfacer is for general finishing tasks on metals.

This bandsaw is used for cutting processes on non-metallic parts such as wood and polymers.

The metallic bandsaw is for cutting processes.

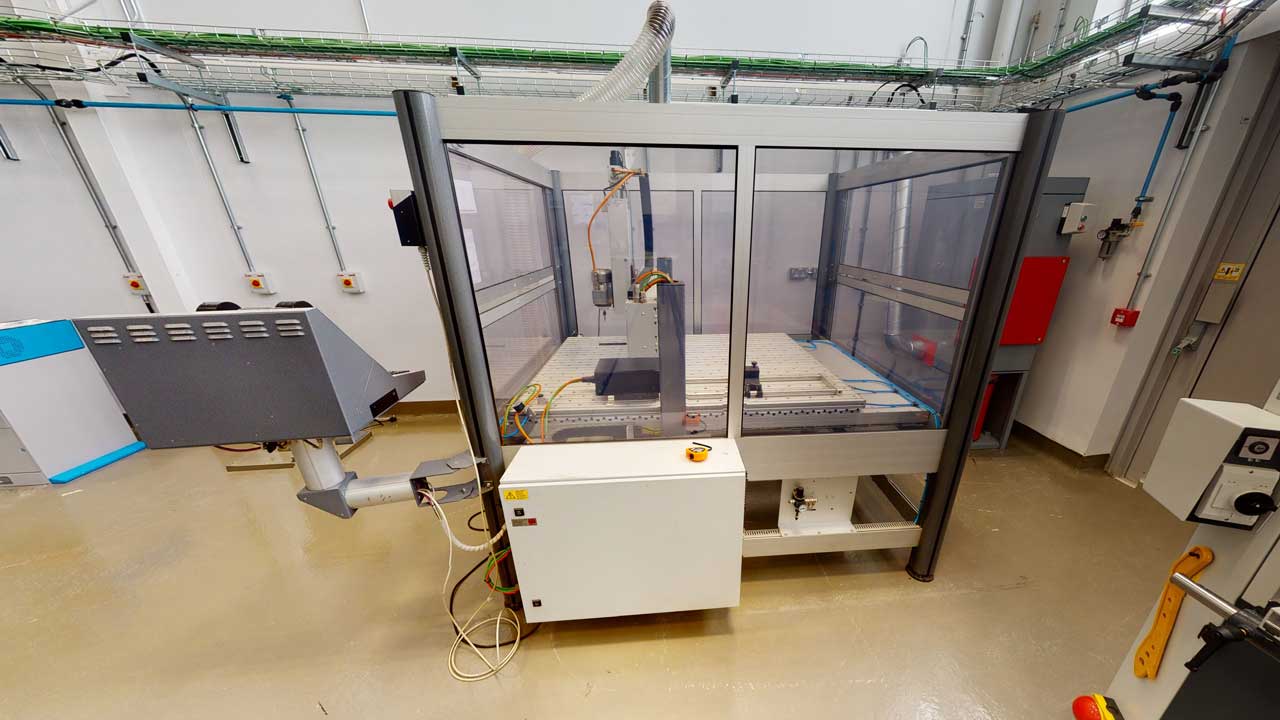

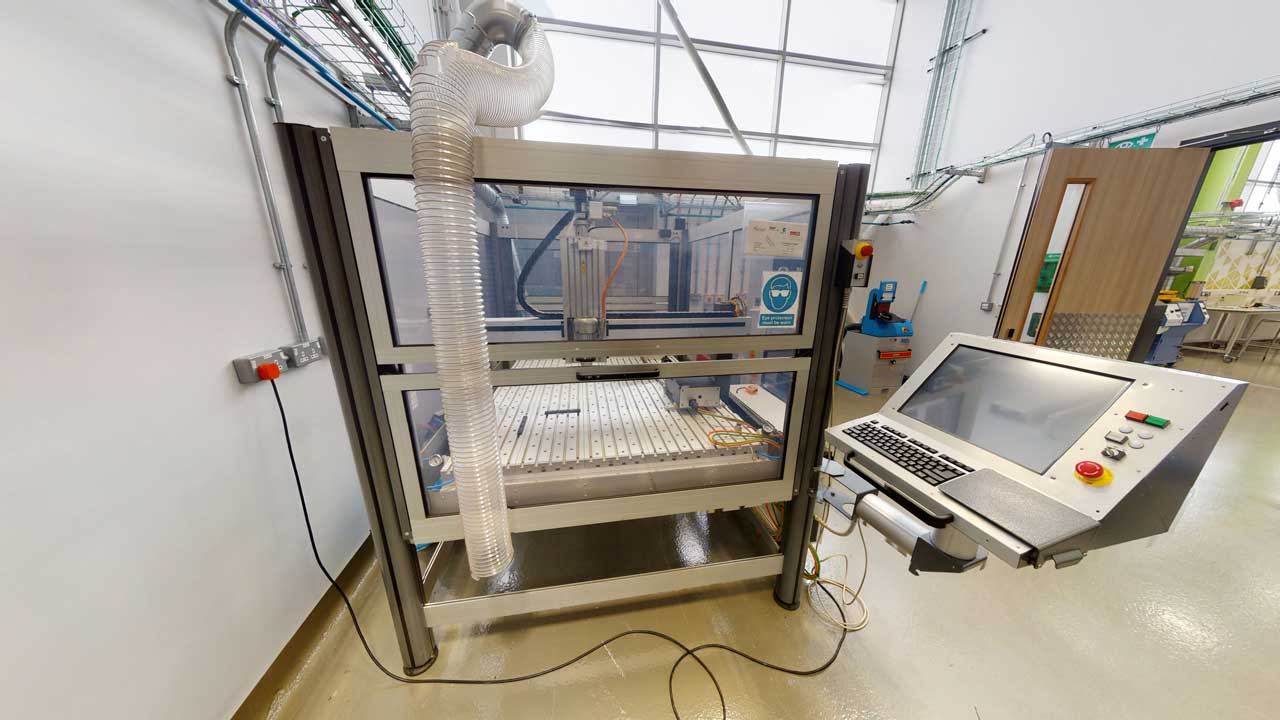

This computer-controlled cutting machine uses a mounted router to machine metal parts.

The bench polisher to create a smooth surface finish.

The pillar drill is for hole making processes in metallic and non-metallic materials.

The CNC lathe allows for precise turning machining processes.

CNC milling machines are used for create precise designs on three-axis stage.

Spray booth for coating processes as a finish manufacturing process.