York scientists' solution to biomass waste ash dilemma

Biomass has become one of the most commonly used renewable sources of energy in the last two decades. But one major problem remains – what to do with the waste ash produced. A team of researchers, led by Dr Duncan Macquarrie from the University of York’s Department of Chemistry, believe they may have the answer.

We have to become more sustainable and re-evaluate what we currently call waste

Dr Duncan Macquarrie

While burning biomass for heat and power could produce as much as 2,000 terawatt-hours of energy by 2020, it is estimated that this would produce 4–15.6 million tonnes of waste ash per year in Europe alone.

Though some of the waste ash produced from the combustion of biomass is currently used in construction, most of it ends up in landfill.

To address this problem, scientists from the University’s Green Chemistry Centre of Excellence, EPR Ely Limited and PQ Silicas UK Limited, have developed an efficient way of converting waste ash into mesoporous structured silica using a biorefinery approach. This has potential high value applications in catalysis, adsorption and separation processes.

“Extracting alkali silicates, which can be used in cement, detergents, catalysts and catalyst supports, is one way of reusing the potentially huge quantities of ash due to be produced in the future,” says Dr Macquarrie.

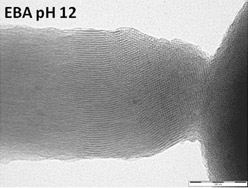

Transmission Electron Micrograph of a MCM-41 produced from Ely Bottom Ash. The well aligned pore structure can be clearly seen in the centre of the image

The improved method of extracting the alkali silicates involves forming alkali silicate solutions, which are then converted into the porous silica, MCM-41, a useful catalyst and molecular sieve.

The results of the research, carried out at a commercial biomass combustion facility, are presented in the Royal Society of Chemistry journal, Green Chemistry.

Dr Macquarrie says: “We have to become more sustainable and re-evaluate what we currently call waste. While most of our work - and most of everyone else’s - has focused on the organic side of things, it is important to remember that there are always inorganic waste streams and that they can become valuable resources too.”

The team plans to expand this work further by examining whether the performance of the porous silica is affected by the silicate source, and if ash from plants that have taken up metals during their lifetime can be used to make metal loaded catalysts.

Further information

- The article ‘Alkali silicates and structured mesoporous silicas from biomass power station wastes: the emergence of bio-MCMs’ by J R Dodson et al, appears in Green Chemistry, 2013, 15, 1203-1210. DOI: 10.1039/c3gc40324f

- The Green Chemistry Centre of Excellence at the University of York is a world leading research centre, led by Professor James Clark, which aims to promote the development and implementation of green and sustainable chemistry and related technologies into new products and processes. The Group is made up of over 70 academic, research, technical and administrative support staff, postdoctoral and postgraduate researchers along with visiting scientists from industry and overseas universities.