Simple Scalable Catalytic Route to Boron Nitride Fibres for Use in Extreme Environments

Posted on Friday 10 October 2025

Research teams from York Chemistry (Weller group) and Oxford Materials (Grobert group) have worked together to develop a new, straightforward, route to hexagonal boron-nitride (hex-BN) fibres. These fibres are lightweight, oxidation resistant, mechanically strong, and electrically insulating materials, that also offer high-strength-to-weight ratio and low density. They are of particular interest as materials for use in extreme environments where carbon fibres can fail. However existing routes to hex-BN fibres use BN polymer precursors which are difficult to source and manufacture .

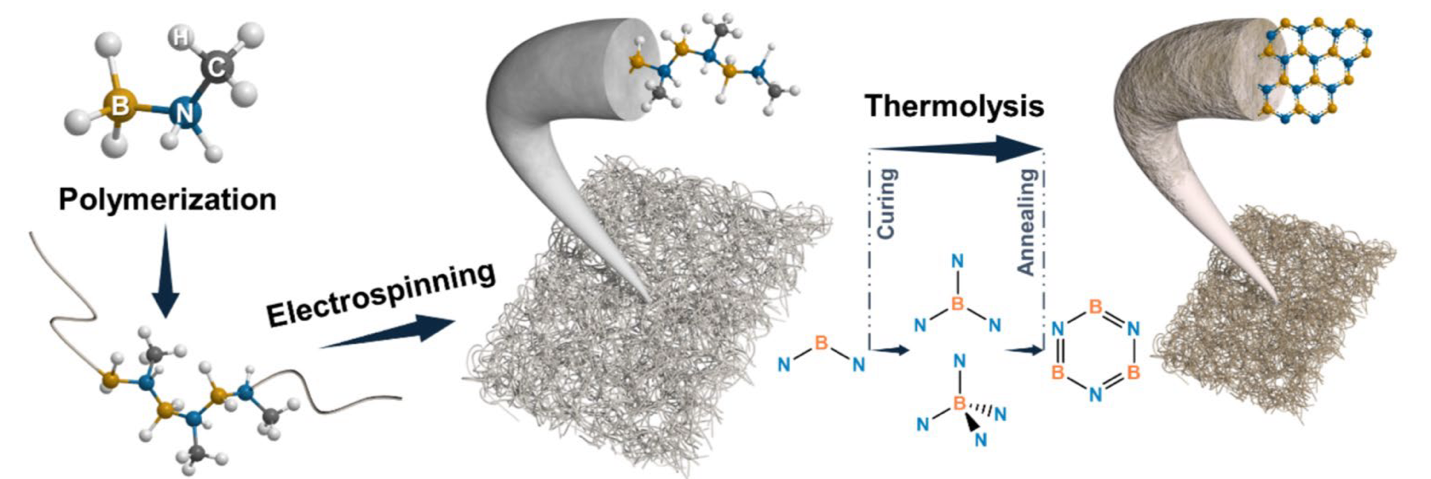

In a new collaborative study, published in Advanced Composites and Hybrid Materials, the efficient catalytic synthesis a new class of BN-containing polymer, polyaminoboranes, has been developed by the Weller group, using a widely-available starting material and very low amounts of catalyst. Importantly, this method enables precise control of the chain-length of the resulting polymer and can be easily performed on a scale useful for onward exploitation. Taking these new polymers, the Grobert group used their expertise in electrospinning to fabricate well-defined polymer fibres that can then be heated to produce hex-BN fibres, which were characterised using a wide range of techniques.

This efficient, catalytic, route to create new bespoke BN-polymers, and the potential scalability of the BN-fibre production process, makes this a very practical approach. It is hoped that these breakthroughs will open up both exploration of the wider uses of BN-containing functional polymers, and the straightforward manufacture of technologically important high-performance BN-composite materials, which could transform the take-up of these materials in next-generation technologies, for example in advanced aerospace applications.

Notes to editors:

This work has been published as an Open Access article in Advanced Composites and Hybrid Materials.