Renewable Feedstocks

The Green Chemistry Centre of Excellence has a proud research track-record of valorisation of biobased feedstocks into chemicals, materials and (bio)energy.

We have discovered that microwaves may be used to selectively activate components of biomass (trees, grasses, crops, agricultural and food waste, macro and micro-algae, etc.), leading to a much more controlled decomposition process than can normally be achieved, e.g. using acid treatment. In this way, we are able to make a range of valuable products including liquid and solid fuels, and chemicals from sustainable sources using green chemical technology. We have proven this at scales from grams to tens of kilograms. We are well positioned through interdepartmental collaborations (e.g. CNAP and the Biorenewables Development Centre) as well as with external academic and industrial collaborations.

In addition, we are interested in carbon dioxide utilisation and catalysts for cyclic carbonate synthesis, which are now being used on industrial scale.

Contact us

Green Chemistry Centre of Excellence

greenchemistry@york.ac.uk

+44 (0)1904 322567

Department of Chemistry,

University of York,

Heslington,

York YO10 5DD,

United Kingdom.

Twitter

Facebook

Case studies

Bilberry press-cake is a by-product from juice production and contains abundant polysaccharides. This research investigated the possibility of applying microwave hydrolysis for multiple chemical recovery.

Trials were carried out at lab and pilot-scale and compared to conventional (Soxhlet) extraction methods where microwaves showed a significant advantage with over 55 per cent conversion achieved. Extraction products included mono and di-saccharides alongside anthocyanins and pectin. A model was proposed for the extraction of bilberry press-cake where conditions (mild to intense) could be selected based on the target products.

Citrus essential oils are used as fragrances in many skin, bath and beauty products. Citrus peel can contain up to four per cent of these essential oils and D-limonene constitutes up to 90 per cent of the oils from orange peel waste and 75 per cent in lemon peel waste. D-limonene can be used in the flavour and fragrance industry but has also been used as a non-toxic solvent or cleaning agent.

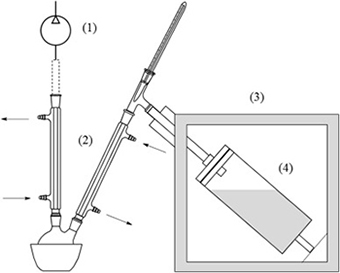

This project used wet orange peel and microwave technology to propose a more scalable and flexible process with lower energy consumption and reduced environmental impact in comparison to conventional methods.

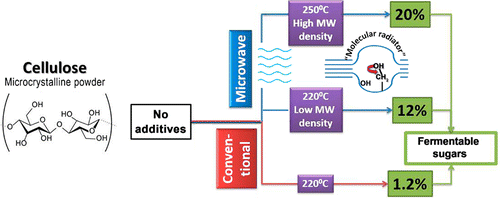

The liquid and solid products obtained following microwave irradiation of microcrystalline cellulose was carried out over a range of temperatures. A mechanism for cellulose interaction with microwaves was proposed with higher temperatures (250⁰C) and higher microwave density resulting in high glucose yields (>20 per cent).

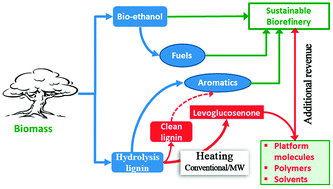

Microwave hydrolysis of waste softwood lignin was carried out in air, at atmospheric pressure without additives. This process converted 40 per cent of the residual saccharides in the lignin with high selectivity (~90 per cent) which represents 8 per cent of the total lignin. Levoglucosenone is a valuable intermediate for the production of fuel and new solvents such as Cyrene™. The lignin remained intact structurally so could be depolymerised further to aromatics.

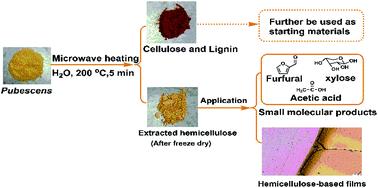

This process facilitated the efficient dissolution of hemicellulose in bamboo at 200⁰C while obtaining hemicellulose free residue which could be used further as a starting material within many industrial processes. A new route to produce hemicellulose-based films that could potentially be used for food packaging was proposed. The overall approach opens up an opportunity for a low cost and sustainable bamboo-based bio-refinery.

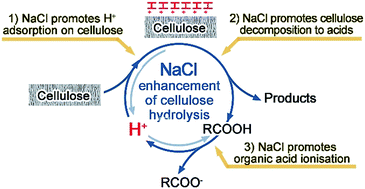

A systematic kinetic study was carried out investigating the effect of NaCl on the cellulose hydrolysis process. It was found that the presence of NaCl simultaneously enhances the generation of acidic products from cellulose decomposition and pushes the generated protons to the surface of cellulose, dramatically increasing surface acidity and facilitating the autocatalytic hydrolysis of cellulose.

Contact us

Green Chemistry Centre of Excellence

greenchemistry@york.ac.uk

+44 (0)1904 322567

Department of Chemistry,

University of York,

Heslington,

York YO10 5DD,

United Kingdom.

Twitter

Facebook