For Business and Industry

In the School of Physics, Engineering and Technology we have world-class expertise, facilities and some of the brightest students in the world. From hybrid cars and next generation computer chips to medical imaging, our research expertise helps inject innovation into products and processes that address strategic business goals. A few examples of our innovation activities are highlighted below.

Magnetic Materials

Data Storage

Due to the continuing rise of global data flows and the ever increasing economic and social connectedness, data storage devices have become an integral part of the 21st century electronics ecosystem. Hard disk drives are at the core of this ecosystem, and they use thin magnetic films for storing and retrieving information. Using high-resolution electron microscopy, Professor Kevin O’Grady and colleagues are able to relate the grain size distributions of particulates within a thin film to the magnitude of the exchange bias – the magnetic response of a material to an applied field. This work has led to the production of next-generation hard drives and the generation of intellectual property relating to a new form of magnetic memory.

Next Generation Hybrid Cars

Professor Roy Chantrell is part of a group led by Toyota Motor Corporation to develop advanced models for permanent magnet alloys. By developing electronic structure and atomistic calculations of these composites, the team is able to design and optimise the magnetic properties of the material. The project aims to double the performance of the magnets by 2020, thereby improving fuel efficiency and carbon footprint.

Materials Characterisation

Advanced materials modelling and simulation

Dr Matt Probert is a core developer of the CASTEP materials modelling software. This program is used to predict the properties of new materials; to better understand existing material properties or to support experimental studies of materials and processes by helping with the interpretation of experiments. The software is marketed by Accelrys Inc and is used by many different companies worldwide including Boeing, Johnson Matthey, Toyota and Unilever. By applying this software the trained researcher is capable of computing many materials properties related to pharmaceuticals, catalysts, polymers and composites, metals and their alloys, batteries and fuel cells etc. Matt's group has a lot of expertise in applying CASTEP and in training others to do likewise.

Dr Keith McKenna utilises theoretical modelling to predict the surface and interfacial properties of polycrystalline materials, metal-oxide thin films as well as nanoparticles. Atomic and nanoscale defects are often detrimental to magnetic, electronic and catalytic material performance. By relating his materials modelling expertise to experimental techniques bulk material properties can be determined and material performance optimised. His research has direct relevance to diverse technological areas including microelectronics, solar cell materials, data storage and optoelectronics.

Biomedical

Dr Kröger is active in the area of nanomaterials with a special focus on biological and bio-inspired materials as well as biomedical applications having established numerous interdisciplinary and international collaborations. Aims of his research are the understanding of the formation process, the structure and function of hard materials such as bone and concrete and the development of new effective nanoparticles for therapeutics and diagnostics in biomedicine. In this context he is collaborating with international companies such as Smith and Nephews in the UK and BASF in Germany. His key techniques are in situ electron microscopy and spectroscopical methods such as Raman microscopy.

Metrology

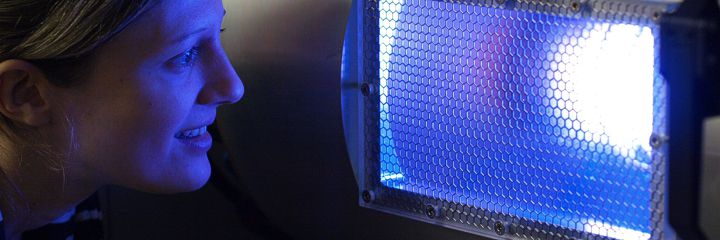

Real-time Metrology

Device manufacturing with controlled molecular precision.

To manufacture complex architectural designs with atom-scale detail requires precision control of the manufacturing process and a mechanistic understanding of material design. Professor Timo Gans leads an academic and industry consortium (including Intel Corporation Ltd, Smith & Nephew and Andor Technology Ltd) to apply plasma etching and advanced optical diagnostics to device invention. Envisaged applications include increasingly sophisticated chip architectures, low power biologically implanted sensors and the realisation of micro-batteries or flexible microelectronics.

Photonics

Photonic Devices and Technology

Prof TF Krauss is one of the most highly cited Photonics researchers in the UK. He has pioneered the field of photonic crystals and nanostructures and has worked with Intel and Agilent to develop photonic circuits in silicon and with Osram to develop high-efficiency LEDs; currently, he is working with Kromek to develop bespoke silicon detectors for the nuclear industry. His group run the cleanroom and nanofabrication suite in the York Nanocentre, so a wide range of structures and devices can be fabricated in-house, aimed at applications in light emitters, photovoltaics and biosensors.

Radiation Detection

Radiation Detection Technology

Professor David Jenkins and Dr Pankaj Joshi have used modern light sensors (eg silicon multiplier) to design next generation scintillator products. Their research has now been utilised to replace conventional photo multiplier technology and is incorporated into Kromek Ltd’s Sigma product. The underpinning research is also being applied to the oil and gas sectors to improve the geophysical measurement of bore holes by utilising novel solid state light sensors. The York team are also developing new detection techniques for dosimetry and calibration work that is critical to medical imaging centres in hospitals.

WRIPA

White Rose Industrial Physics Academy

The White Rose Industrial Physics Academy (WRIPA) is a partnership between the five universities in Hull, Leeds, Nottingham, Sheffield and York, plus technical industries from across the region. WRIPA has received external funding of £3.0 million from the Higher Education Funding Council for England (HEFCE) and the Office for Students (OfS).

WRIPA supports technical sectors to innovate and grow through the provision of highly skilled physics graduates and aims to connect students and graduates with the wealth of career opportunities available.

The Academy’s role is to facilitate collaborations between physics students and industry, through internships, Year In Industry placements, final year projects and careers activities. WRIPA also organises the UK’s largest physics-focused recruitment fair.

For further information about the White Rose Industrial Physics Academy go to www.wripa.ac.uk

YPI

York Plasma Institute

Dr Kate Lancaster and the YPI work with industry to support the commercialisation of emergent technologies in bio-medicine, efficient lighting, microchip fabrication and packaging. Working with Culham Centre for Fusion Energy, YPI also enables UK industry to benefit from the €10bn ITER construction programme. ITER is a large international project based in France that offers many high technology contracts for industry.