York physicists help drive forward development of 'green' cars

Auris Hybrid Touring Sports. Image courtesy of Toyota.

Physicists from the University of York are playing a key role in the development of high performance magnetic materials which will make electric cars a more realistic option for the future.

The team from the University’s Department of Physics are working on the 10-year MagHEM Project, which is funded by the Ministry of Economy, Trade and Industry, Japan.

The project, which was launched in November 2012, aims to achieve a factor two increase in performance.

It is hard to overstate the environmental impact of a successful outcome of this project

Professor Roy Chantrell

Researchers from the Condensed Matter Physics group at York are working with colleagues from the University of Exeter and St. Pölten University of Applied Sciences near Vienna on the theoretical modelling aspects of the project.

This involves carrying out electronic structure and atomistic calculations to study the underlying physics of nanostructured composite materials and applying the understanding to any proposed material designs.

Professor Roy Chantrell, from York’s Department of Physics, says, “It is very exciting to be working on a project to develop advanced models providing fundamental physical understanding and, at the same time, apply the models to the design and optimisation of materials for important applications.

“It is hard to overstate the environmental impact of a successful outcome of this project, since a factor two improvement in automotive applications would contribute significantly to reducing greenhouse gas emissions.”

As well as increasing performance, the project aims to remove Dysprosium (Dy) from permanent magnet alloys. In hybrid cars, the performance of permanent magnets, which use an alloy of Neodymium (Nd) and iron (Fe), currently has to be enhanced by the addition of Dysprosium, which gives it adequate performance at high temperatures. However, the scarcity of Dysprosium – a so-called ‘Rare-Earth’ material - is a serious problem.

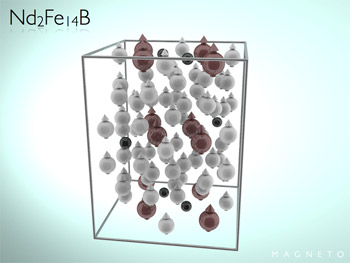

An NdFeB unit cell. Credit: Dr Richard Evans

“The magnetic properties of Dysprosium are not understood and the interactions between atoms are difficult to calculate,” says Professor Chantrell. “Therefore, developing a theoretical understanding of Dy and finding a substitute is an exciting challenge for the models we are developing at York.”

York researchers were invited to join the project team by Toyota because of the innovative modelling techniques being developed at the University. These combine atomistic and electronic calculations and are already proving important in the development of new approaches to magnetic recording media.

“The techniques for atomistic and electronic modelling are very different, but the new materials being developed at nanoscale are so complicated that we need to find ways of linking the models to create a more powerful approach,” says Professor Chantrell.

As well as helping create new environmentally friendly cars, the ‘green magnet’ project could have a number of other important applications, such as improving the efficiency of windmills, and the battery life and power of handheld tools.

Another aspect of the work of the University’s Department of Physics is also proving to be of major importance to companies such as Toyota in Japan.

A consortium of top UK academics is developing computer codes to provide new insights into existing and predicted materials using the national supercomputer (HECToR).

Computer simulation is an important element of research and development and the quality control process, and is used by both academia and industry

Dr Matt Probert

Led by the University of York, the UK Car-Parrinello Consortium (UKCP) is made up of 19 partner institutions, and uses computer simulation and the power of quantum physics to calculate the properties of materials at the level of atoms and electrons.

The world-leading CASTEP code – UKCP’s flagship computer simulation code – is increasingly being used by research and development laboratories in Japan and elsewhere.

CASTEP is continually evolving and can simulate the properties of any material using any element from the periodic table from hydrogen to uranium. Globally, it is used by over 650 research groups, as well as more than 100 major companies, including Toyota and Sony. It is used widely in the UK, Japan, the United States and China.

Applications range from generating new materials for jet engine blades, to improving our understanding of the materials at the Earth’s core, to developing new materials for energy generation.

Principal Investigator Dr Matt Probert, from the University of York’s Department of Physics, says, “Computer simulation is an important element of research and development and the quality control process, and is used by both academia and industry. It is used for purposes as diverse as looking at how defects in materials work, to developing new alloys for car batteries for electric cars, to modelling the semi-conductors that make up chips.

“As they are now becoming so straightforward to use, computer simulation programs are increasingly being used by research and development laboratories as part of their everyday toolkit for understanding and interpreting experiments.”

Further information

- Department of Physics

- The UK Car-Parrinello Consortium (UKCP) includes researchers from the University of Cambridge, Daresbury Laboratory, Durham University, Imperial College London, Kings College London, the University of Edinburgh, University of Liverpool, University of Oxford, University of Southampton, Queens University Belfast, University College London and the University of York.

- The CASTEP code