Safety assurance of cooperating construction equipment in semi-automated sites (SUCCESS)

Moving towards the use of a fleet of autonomous construction vehicles by assuring their safety when they work together as a system-of-systems.

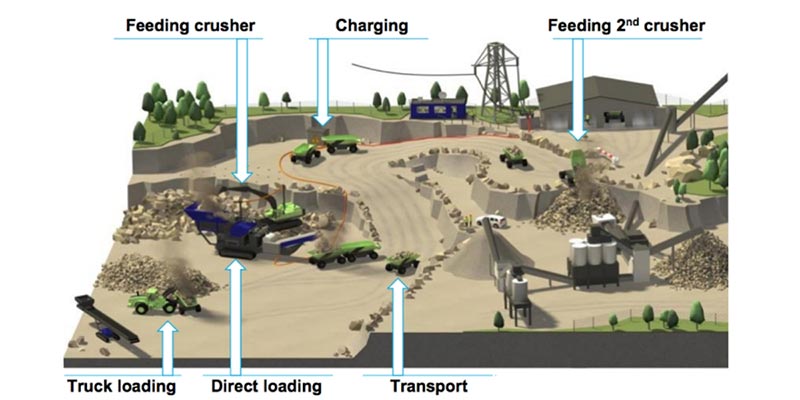

The main focus of the SUCCESS project was the assurance of safety for a quarry site case where numerous machines interacted and collaborated. The team conducted research on hazard/safety analysis methods, adapted them to the quarry site requirements, and incorporated best practices into a new assurance methodology that is also applicable to similar classes of system-of-systems (SoS).

Contact us

Assuring Autonomy International Programme

assuring-autonomy@york.ac.uk

+44 (0)1904 325345

Institute for Safe Autonomy, University of York, Deramore Lane, York YO10 5GH

Project report

The full project report describes the outcomes of the team's work towards the safety assurance of the quarry site case.

The challenge

Quarry sites require a series of repetitive and sometimes dangerous tasks. A system of cooperating construction machines offers an opportunity to take humans out of harm’s way whilst providing a cost-effective and more environmentally friendly process for construction. But current safety standards and processes focus on single machines. In the case of cooperating autonomous machines, critical situations may be missed if safety assurance is applied for single machines, ignoring different application scenarios.

The research

The SUCCESS demonstrator project explored numerous aspects in the safety assurance of cooperating SoS, with a special focus on the construction machinery domain.

Specifically, the project:

- highlighted the challenges in hazard analysis of SoS

- demonstrated a digital twin-based approach for simulation and verification of safety requirements

- evidenced the potential of geofences for dynamic risk management

- outlined an end-end tool framework for safety analysis

The project used a quarry site at Volvo Construction Equipment - the “Electric Site” - to give a real environment in which to study the fleet of machines working together as a SoS.

The results

You can read about all of the results from the project in the full project report. The main results include:

- the team proposed new ideas for the hazard analysis of SoS, including a state-based extension to System Theoretic Process Analysis (STPA) and the team’s “SafeSoS” approach. SafeSoS offers a hierarchical process for specifying a SoS and using those specifications for performing a safety analysis.

- the Volvo training simulators at Mälardalen University were adapted and extended to form a digital twin of the Electric Site. This enabled the team to verify the safety requirements of their collaborating autonomous systems and to implement and check multiple safety-critical scenarios.

- the project team has shown the potential of different types of geofences for dynamic risk management during the operational phase.

- an end-to-end tool framework was defined by the team that incorporates both process and product-based evidence, safety contracts, and dynamic assurance

SUCCESS guidance is available in the Body of Knowledge:

- 1.2 Identifying hazardous system behaviour

- 2.4. Controlling interactions with other systems (identify how interactions between the RAS and other systems may give rise to unsafe behaviour)

- 2.4. Controlling interactions with other systems (manage interactions between the RAS and other systems to ensure they do not result in unsafe behaviour)

- 3.1 Identifying potential deviation from required behaviour

- Javed, M., Ul Muram, F., Hansson, H., Punnekkat, S., and Thane, H. "Towards Dynamic Safety Assurance for Industry 4.0". In Journal of Systems Architecture (JSA), Oct 2020

- Baumgart, S., Fröberg, J., and Punnekkat, S. "A Process to Support Safety Analysis for a System-of-Systems". 31st International Symposium on Software Reliability Engineering (ISSRE Oct 2020)

- Ul Muram, F., Javed, M., Hansson, H., and Punnekkat, S. "Dynamic Reconfiguration of Safety-Critical Production Systems". 25th IEEE Pacific Rim International Symposium on Dependable Computing (PRDC Sep 2020 - to be presented in December 2021)

- Javed, M., Ul Muram, F., Fattouh, A., and Punnekkat, S. "Enforcing Geofences for Managing Automated Transportation Risks in Production Sites". Workshop on Dynamic Risk managEment for Autonomous Systems (DREAMS/EDCC Sep 2020)

- Ul Muram, F., Javed, M., Punnekkat, S. "System of Systems Hazard Analysis Using HAZOP and FTA for Advanced Quarry Production". International Conference on System Reliability and Safety (ICSRS-Nov 2019)

- Baumgart, S., Fröberg, J., and Punnekkat, S. "A State-based Extension to STPA for Safety-Critical System-of-Systems". International Conference on System Reliability and Safety (ICSRS-Nov 2019)

As an independent assessment body undertaking third party assessments we have been able to use the SUCCESS project’s work to determine what is feasible within existing regulations and safety standards and, when applicable, what could be used to support the development of future standards.

Henrik Thane, CEO, Safety Integrity AB

Project partners

- Professor Sasikumar Punnekkat (principal investigator) Mälardalen University

- Professor Hans Hansson (co-investigator) Mälardalen University

- Stephan Baumgart (co-investigator) Volvo Construction Equipment

- Dr Henrik Thane (co-investigator) Safety Integrity AB

Contact us

Assuring Autonomy International Programme

assuring-autonomy@york.ac.uk

+44 (0)1904 325345

Institute for Safe Autonomy, University of York, Deramore Lane, York YO10 5GH