Professor Avtar Matharu

01904 324187

Email: avtar.matharu@york.ac.uk

Professor Avtar Singh Matharu is Senior Lecturer, Deputy Director of the Green Chemistry Centre of Excellence (GCCE) and PGT MSc Green Chemistry and Sustainable Industrial Technology Course Director. The GCCE is an internationally-leading academic facility for the provision of excellence in green and sustainable chemical technologies, processes and products. He has been External Examiner at Keele University for their Postgraduate Taught MSc in Environmental Science & Green Technologies. He is Editor-in-Chief of Elsevier Current Research in Green and Sustainable Chemistry.

Avtar specialises in gaining high additional chemical value from otherwise low-value resources or waste such as unavoidable food supply chain wastes, developing sustainable supply chains and circular economy within the context of biorefineries.

Recent Research Projects

EPSRC: Systems Change

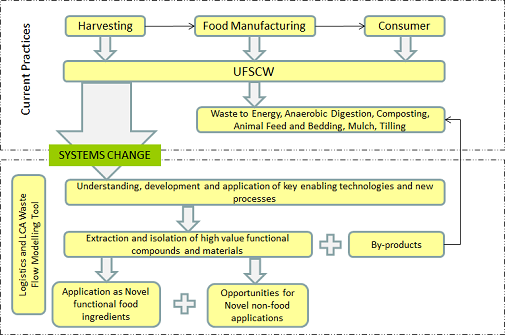

Whole systems understanding of unavoidable food supply chain waste for re-nutrition (2017-2018, £800,000). In collaboration with University of Nottingham and Loughborough University with External Advisory partners from 8 different companies from the UK food manufacturing sector.

This project explores four different feedstocks (brewers spent grains, pea vine waste, out of specification potatoes, out of specification citrus fruits) and undertakes four inter-related tasks to verify new technologies and process-driven whole systems change understanding of unavoidable food supply chain waste within the context of a circular economy.

InnovateUK, BBSRC, EPSRC IB Cat: Round 3 Early stage translation

Integrated energy efficient microwave and unique fermentation processes for pilot scale production of high value chemicals from lignocellulosic waste (2016-2020, £3.2 M). In collaboration with University of Bath and C-Tech Innovation Ltd, Croda, AB Agri.

Recently, we reported an innovative one-step microwave (MW) process for the depolymerisation of bio-wastes. This key enabling technology achieves high sugar yields despite low energy inputs. Though a range of inhibitors are also formed in the process which limit the growth of most yeasts, we have shown that the robust yeast Metschnikowia pulcherrima (Mp) thrives on this feedstock to produce valuable 2-phenylethanol, arabinitol and a microbial oil akin to palm oil. Therefore this project aims to develop a pilot scale multi-product process by coupling these breakthroughs in low energy waste treatment and unique fermentation to produce high value chemicals.

This is one of four national pilot programmes aimed at widening participation in Engineering and Physical Sciences Research Council (EPSRC) doctoral training, specifically those from industry and other non-academic backgrounds. Eight 4-year PhD studentships funded by the Engineering and Physical Sciences Research Council are offered to research in Leadership and Excellence in Circular, Resource-efficient, Sustainable Manufacturing within chemical, biological and allied sciences at the University of York.

The chemicals sector is one of the largest UK manufacturing sectors with a turnover of £48.7bn and employs ca. 140,000 people. The UK Chemistry Council’s Chemistry Strategy highlights a greater emphasis on sourcing of renewable raw materials, ensuring products are free from pollutants and innovating to reduce their carbon footprint. Recent Science Innovation Audits (Northern Powerhouse: Chemical and Process Sector Science and the Bioeconomy in the North of England) highlight the importance of our chemicals and bioeconomy sectors, interconnectivity of chemistry and biology, importance of training, re- and up-skilling, and continual professional development in physical and biological sciences.

In order to protect and enhance our assets, knowledge and infrastructure, businesses will need to transform their current practices, which are often linear and resource-depleting, in partnership with academia to develop leadership and excellence in circular, resource efficient, sustainable manufacturing. This project explores new, inclusive and flexible, pathways to doctoral training to enable mobility from industry to academia through a supportive PhD programme.